How Does Laser Scanning Work – a simplified version

Laser scanning is similar technology to traditional surveying in that it uses the speed of light to measure distances along with the angle of the laser beam to determine the x,y,z coordinates. However whereas an EDM (or total station) takes discrete single measurements the latest laser scanner can capture up to 2 million measurements per second.

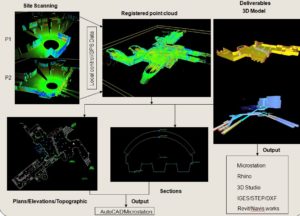

This results in a cloud of points (or pointcloud) and when the individual pointclouds from each scan position are registered together it produces an overall pointcloud of the area or structure.

From this overall pointcloud a range of deliverables can be produced.

These include as-built or more correctly in most cases as-is 2D drawings, 3D models, cross-sections, panoramic images, animations and more industry specific such as gauging and movement monitoring for the railway.

So how can Laser Scanning save you Money?

Let’s consider there is a refurbishment required of for example a:

- building

- bridge

- tunnel

- process plant

- plant room

- baggage handling area

- railway station

For the building the architect will require accurate detailed plans or often a 3D model of the existing features such as the structural elements, doors and windows, fixed fittings etc. So the cost advantages of using the laser scanner in this case are :

- To capture this information on site using an EDM and Disto will take up to 10-15 times longer than using a laser scanner.

- The onsite costs are often less due to the faster survey time

- More data can be captured in a much shorter time – less likelihood of missing information requiring return trips to site

- Structural elements can be captured more accurately – less likelihood of design errors leading to rework

- Scanning can usually be undertaken from ground or floor level minimising safety requirements of working at height and perhaps needing specialist equipment

- Jetstream images from each scan position greatly assist the design phase compared to photographs which need to be accurately catalogued which takes time and usually do not provide sufficient coverage again resulting in return trips.

- Accurate survey information will result in less rework on site due to design errors using incorrect data

As can be seen from above there are significant savings to be made when using laser scanning surveys allied to traditional survey techniques.

In the UK we do not tend to identify the cost of rework on a project but the USA has collated metrics in the process industry which show that rework costs on refurbishment projects can be reduced from 10% to 1-2% of the construction costs by using accurate as-built data from laser scanning surveys from the outset.

Similarly using laser scanning to survey a new build prior to the start of the MEI installation will allow the as-built structure to be compared to the design and to highlight any discrepancies. This can again result in a significant cost saving as redesigning for example a ventilation duct or cable tray which clashes with a structural element that is not quite in the “correct” position is an expensive process at this stage of the project and can lead to delays.

Source: Scantech International LTD

The post Can Laser Scanning Surveys save you Money? appeared first on UK Construction Online.

Walang komento:

Mag-post ng isang Komento